Industry news

- Home > News > Industry news

what is The rectangular copper wire continuous rolling mill?

2023-07-08

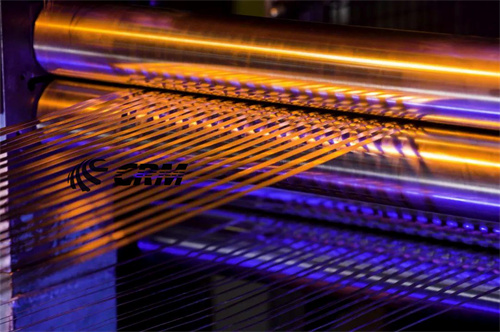

The rectangular copper wire continuous rolling mill exemplifies a remarkable apparatus employed in the metalworking industry, specifically designed for the uninterrupted rolling of copper wire. Its purpose is to transform copper billets or rods into the desired rectangular cross-sectional shape by subjecting them to a sequential series of rolls.

Comprising a set of rolls, a transmission system, and a control system, the rectangular copper wire continuous rolling mill embodies a harmonious blend of essential components. To facilitate the rolling process, the copper billets or rods undergo preliminary treatments such as heating and cleaning, ensuring enhanced malleability. Subsequently, they embark on a transformative journey within the tandem rolling mill, traversing through an array of rolls that progressively diminish the cross-sectional dimensions until the coveted rectangular form is achieved.

The rolls of the tandem mill, ingeniously engineered, possess the capability to systematically adapt their spacing and contour, seamlessly accommodating the copper wire's gradual reduction. The drive system orchestrates a symphony of power and velocity, endowing the rolling operation with efficiency and efficacy. Meanwhile, the control system, serving as a vigilant sentinel, diligently monitors and regulates the intricate parameters of the rolling process, upholding the exacting standards of the final product's quality and precision.

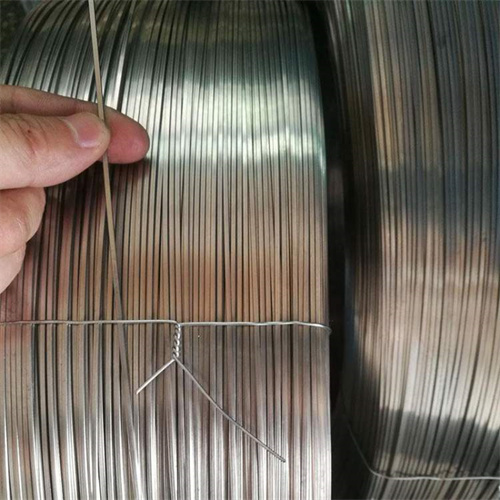

With its versatile applications, the rectangular copper wire rolling mill plays an instrumental role in various industries, where it serves as a stalwart producer of cables, electrical equipment, communication devices, and an array of copper-based products. This exceptional machinery begets high-precision rectangular copper wires, characterized by their unwavering dimensional consistency and exceptional mechanical properties, perfectly tailored to meet the diverse requirements of different sectors.