Stainless Steel Welding Wire - What Is It?

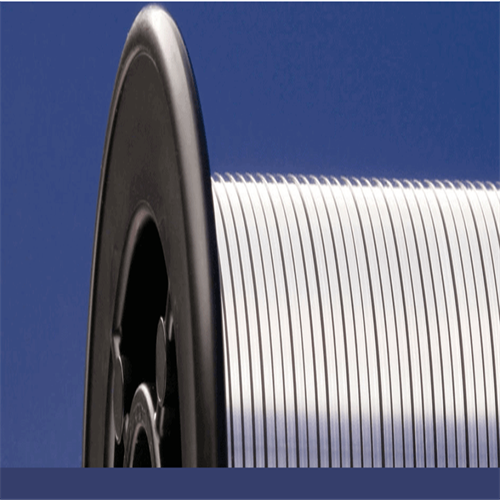

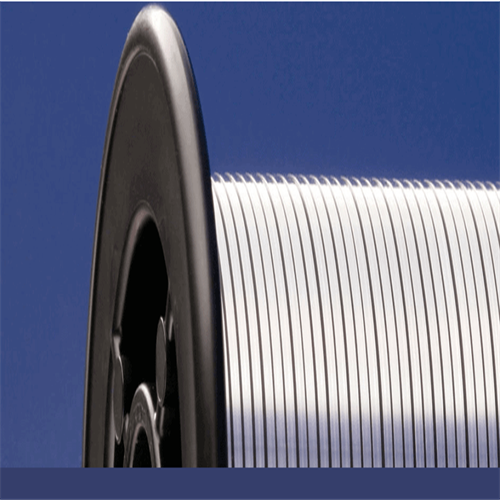

A stainless steel welding wire is a consumable material that is used to join stainless steel components and to fabricate structures using a variety of welding processes. A stainless steel is a family of corrosion-resistant and heat-resistant steel alloys that is known for its strength and durability. It is important to use specific welding wires when welding stainless steel in order to ensure a strong, corrosion-resistant, and aesthetically pleasing weld that is corrosion-resistant.

Product Detail

Stainless Steel Welding Wire - What Is It?

A brand WANJING stainless steel welding wire is a consumable material that is used to join stainless steel components and to fabricate structures using a variety of welding processes. A stainless steel is a family of corrosion-resistant and heat-resistant steel alloys that is known for its strength and durability. It is important to use specific welding wires when welding stainless steel in order to ensure a strong, corrosion-resistant, and aesthetically pleasing weld that is corrosion-resistant.

The Classification Of Stainless Steel Welding Wires

There are two types of stainless steel welding wire: stainless steel solid core welding wire and stainless steel flux core welding wire.

For inert gas shielded welding (TIG, MIG), stainless steel solid core welding wire can be used. In addition, it can also be used for submerged arc welding. Aside from achieving high welding efficiency, MIG welding of stainless steel can also be easily automated. It is widely used for cladding and thin plate welding. MIG welding wires contain the same chemical composition as TIG welding wires. However, for some stainless steel varieties, there is also a MIG welding wire with a higher SI content, such as ER308Si, ER309Si, etc. corresponding to ER308 and ER309 welding wires. In addition to reducing the surface tension of the droplet metal, the particles become finer, overspraying becomes easier, and the arc becomes more stable as a result of the high Si content. It can also improve the wettability of the molten metal, making the weld bead ripples more beautiful and less susceptible to defects such as incomplete penetration, slag inclusions, and pores. The chemical composition of solid stainless steel welding wire used for submerged arc welding is the same as that of stainless steel welding wire used for gas shielded welding, however it should be equipped with a non-manganese, medium silicon and fluorine smelting flux or a manganese-free, low silicon and high fluorine flux.

Performance Advantages Of Stainless Steel Welding Wire

The main application of stainless steel flux-cored welding wire is MAG welding, which is an efficient and simple method of welding stainless steel. A MAG welding machine has the following characteristics; 1) when compared with manual welding, the deposition speed is 2-4 times faster and the deposition efficiency is as high as 90% (stainless steel electrodes have a deposition efficiency of only 55%). A wide range of current and voltage can be used, welding conditions can be set relatively easily, and semi-automated and automated welding can be easily performed. 3) Good slag removal performance and glossy weld bead surface. Furthermore, there is very little spatter, excellent arc stability, and qualified X-rays.

Among Our Main Products Are The Following:

Flat Wire Precision Rolled Products

Contacting Us Today.

Phone: +86-13641919128

Email: songjiangzh@outlook.com

Whatsapp: +86-13641919128

Website: https://wanjwire.com/products/