Company News

- Home > News > Company News

Stainless Steel Flat Wire for Medical Orthodontic Uses

2025-01-23

Stainless Steel Flat Wire for Medical Orthodontic Uses: Precision and Quality by WANJING WIRE

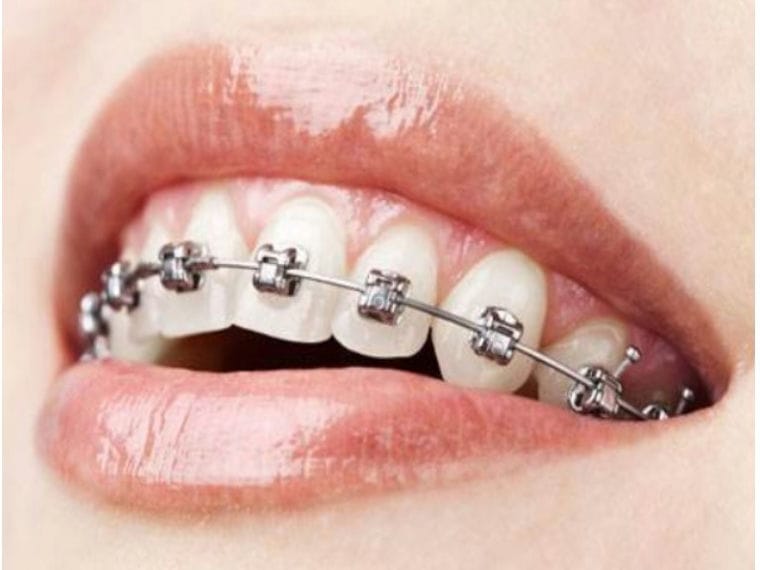

In orthodontics, precision and durability make all the difference. Among the essential materials used in braces and other dental tools, stainless steel flat wire stands out for its exceptional performance. Whether you're a dental professional or a distributor, finding the right supplier who guarantees both quality and affordability can be challenging. Thankfully, WANJING WIRE, the best manufacturer in China, delivers top-notch stainless steel flat wire for medical orthodontic applications.

In this article, we’ll explore the benefits of stainless steel flat wire, its role in orthodontics, and why WANJING WIRE is your go-to partner for high-quality products at the best price in China.

What Are the Common Sizes of Stainless Steel Flat Wires Used in Orthodontics?

Stainless steel flat wires used in orthodontics are available in a range of common sizes to accommodate various treatment needs. These sizes are meticulously designed to ensure precision, strength, and flexibility, which are crucial for effective tooth movement and patient comfort.

Orthodontists often choose flat wire sizes based on the specific stage of treatment, such as initial alignment or fine-tuning tooth positions. Standard dimensions typically fall within widths of 0.016 inches to 0.021 inches and thicknesses ranging from 0.016 inches to 0.025 inches, though customized sizes are also widely used for specialized applications.

By offering versatility in sizes, stainless steel flat wires enable orthodontists to deliver highly tailored and efficient treatments, ensuring optimal results for patients.

What Are the Common Sizes of Stainless Steel Square Wires Used in Orthodontics?

Stainless steel square wires are essential components in orthodontics, offering the precise control and durability needed for effective tooth alignment. These wires are available in standard sizes that cater to different treatment stages and requirements, enabling orthodontists to achieve optimal results.

Common sizes of stainless steel square wires typically include:

• 0.016 × 0.016 inches

• 0.017 × 0.017 inches

• 0.018 × 0.018 inches

• 0.019 × 0.019 inches

• 0.021 × 0.021 inches

Orthodontists select these sizes based on treatment objectives, such as initial alignment, space closure, or finishing adjustments. The square cross-section of the wire provides excellent torque control, making it ideal for more advanced stages of treatment where precise tooth movement is required. Our factory can provide all of the above sizes

Why Stainless Steel Flat Wire Plays a Crucial Role in Orthodontics

Orthodontists rely on stainless steel flat wire to meet the demands of strength, flexibility, and precision in their treatments. This material allows them to make precise adjustments while providing patients with greater comfort throughout the process.

Flat wire actively delivers several key benefits:

• Enhances Control: Orthodontists use flat wire to achieve precise adjustments, making treatments more efficient and predictable.

• Provides Strength and Durability: Stainless steel resists wear and tear, maintaining its performance over time and ensuring effective tooth alignment.

• Prevents Corrosion: Flat wire fights rust and corrosion, even in the moist and acidic conditions of the mouth, retaining its quality throughout the treatment.

• Improves Patient Comfort: With its smooth surface and controlled elasticity, flat wire reduces discomfort while optimizing results.

By choosing high-precision flat wire, orthodontists consistently deliver reliable and effective treatments that leave patients with lasting, high-quality outcomes.

Why China Leads in Orthodontic Wire Manufacturing

China has established itself as a global leader in producing stainless steel flat wires and other orthodontic materials. Manufacturers like WANJING WIRE set the standard with their focus on innovation, efficiency, and affordability, making them the preferred choice for orthodontic professionals worldwide.

Key advantages of sourcing from China include:

• World-Class Technology: Chinese manufacturers continually invest in advanced machinery and processes, ensuring they produce precision wires that meet and exceed global standards.

• Cost-Effectiveness: Efficient production methods in China enable manufacturers to deliver premium-quality products at competitive prices, benefiting both suppliers and end users.

• Global Reach: Companies like WANJING WIRE have built extensive networks, ensuring seamless supply chain operations for clients across Asia, Europe, and North America.

• Skilled Workforce: China’s large pool of highly trained professionals enables manufacturers to maintain exceptional quality standards and keep up with increasing global demand.

• Commitment to Innovation: Chinese manufacturers actively develop new techniques and materials to address evolving industry needs, helping orthodontic professionals achieve better treatment outcomes with cutting-edge solutions.

China’s orthodontic wire manufacturing industry combines expertise, efficiency, and forward-thinking innovation, making it the leading destination for sourcing high-precision materials. WANJING WIRE exemplifies these advantages, delivering unmatched quality and service to clients worldwide.

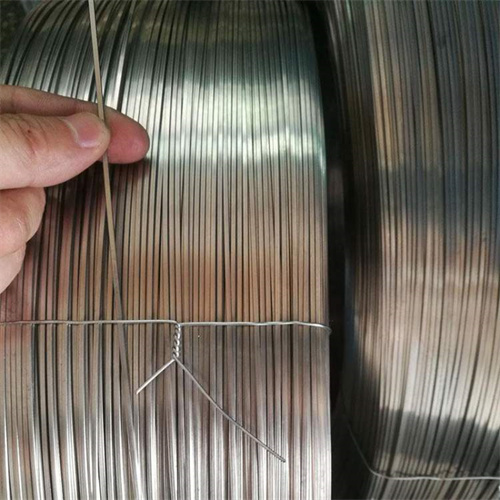

Common Packaging Methods for Stainless Steel Flat Wire in Orthodontics

Manufacturers use several methods to package stainless steel flat wires for orthodontics, ensuring the wires stay protected, clean, and undamaged during storage and transport.

1. Coil Packaging: They coil the wires and wrap them in plastic or shrink film to prevent tangling and shield them from moisture and dust.

2. Spool Packaging: Manufacturers wind wires onto spools, making them easy to handle and store. Labels on the spools include size, material, and batch details.

3. Straight-Length Bundles: They cut wires into straight lengths, bundle them, and secure them with protective sleeves to avoid bending or scratching.

4. Custom Packaging: Some manufacturers offer vacuum-sealed wraps, anti-static bags, or branded boxes to meet specific client needs.

5. Bulk Packaging: For large orders, they pack multiple coils or bundles into durable cartons or crates for safe delivery.

These methods help manufacturers deliver flat wires in perfect condition, ready for use in orthodontic applications.

How WANJING WIRE Drives Your Success

WANJING WIRE does more than manufacture stainless steel flat wires—they actively collaborate with clients to ensure their success. By offering customized solutions, dependable service, and premium-quality products, WANJING WIRE empowers orthodontists, distributors, and clinics to achieve their goals.

Here’s why professionals rely on WANJING WIRE:

• Delivers Precision Excellence: Their high-precision flat wires elevate the quality and effectiveness of orthodontic treatments, ensuring superior patient outcomes.

• Offers Cost-Effective Solutions: By combining top-notch quality with competitive pricing, they help clients stay ahead in a demanding market.

• Builds Lasting Partnerships: With a foundation of trust, reliability, and exceptional service, WANJING WIRE fosters strong, long-term collaborations that support growth and success.

By choosing WANJING WIRE, you gain more than a supplier—you gain a partner dedicated to your success.