Company News

- Home > News > Company News

Stainless Steel Flat Wire: Why China Stands Out as the Top Manufacturer

2025-01-11

Stainless Steel Flat Wire: Why China Stands Out as the Top Manufacturer

In today’s rapidly evolving industrial landscape, stainless steel flat wire has become a vital component in various sectors, including automotive, electronics, construction, and food processing. Known for its strength, corrosion resistance, and adaptability, stainless steel flat wire is used in products that demand durability and precision. As a global leader in manufacturing, China has established itself as a premier source for high-quality stainless steel flat wire. In this article, we will explore why China is considered the best destination for sourcing stainless steel flat wire, and how working with top manufacturers can benefit your business.

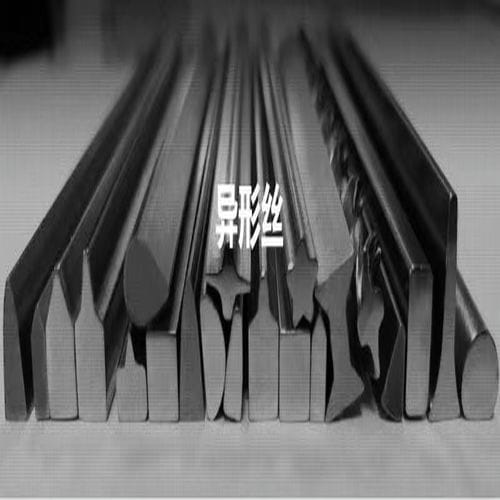

What is Stainless Steel Flat Wire?

Stainless steel flat wire is a versatile material made by shaping stainless steel into a flat, rectangular form. Unlike round or hexagonal wire, flat wire offers a wide range of applications due to its flexibility in design and manufacturing. It is typically produced by drawing and rolling stainless steel strips into various thicknesses and widths, depending on the specific needs of the customer.

Benefits of Stainless Steel Flat Wire

Stainless steel flat wire is preferred across many industries because of its outstanding characteristics:

Corrosion Resistance: Stainless steel is naturally resistant to rust and corrosion, making it ideal for environments exposed to moisture, chemicals, or heat. This makes flat wire an excellent choice for industries such as marine, chemical processing, and food processing.

Durability: Stainless steel is known for its exceptional strength and long-lasting durability. This makes it a reliable material for manufacturing components that are subject to wear and stress, such as springs, electrical contacts, and mechanical parts.

Versatility in Use: The adaptability of stainless steel flat wire allows it to be used in a wide array of applications, from electrical conductors to structural elements in buildings, automotive components, and even medical devices.

Aesthetic Appeal: Stainless steel’s natural sheen and modern look make it highly sought after in decorative and architectural applications, adding both functionality and style.

High Strength-to-Weight Ratio: Stainless steel flat wire boasts a superior strength-to-weight ratio, making it an ideal material for applications that require lightweight but strong components, such as in the aerospace or automotive sectors.

The Manufacturing Process of Stainless Steel Flat Wire

The production of stainless steel flat wire is a highly specialized process that requires precision and expertise. Here's an overview of how it is made:

Material Selection: The process begins with the selection of high-grade stainless steel alloys, typically containing iron, chromium, and nickel. These alloys provide the wire with its corrosion resistance and mechanical strength.

Hot Rolling: In the initial stage, the stainless steel is heated to high temperatures and passed through rollers to form strips of varying thickness. This step is crucial for creating the flat shape and ensuring the wire retains its strength.

Cold Drawing: After hot rolling, the stainless steel strips are drawn through a die to reduce their thickness further. This cold drawing process increases the wire's tensile strength and improves its dimensional accuracy.

Annealing: The wire is then heated and slowly cooled in a controlled environment. This process, known as annealing, helps reduce internal stresses and enhances the flexibility of the wire.

Surface Treatment: To ensure the wire is resistant to corrosion and has a smooth surface finish, it undergoes treatments such as passivation or pickling, which remove impurities and prevent oxidation.

Cutting and Packaging: After the wire meets the desired specifications, it is cut to the required lengths and packaged for distribution.

Why Choose China as Your Stainless Steel Flat Wire Supplier?

China has earned its reputation as a global leader in stainless steel production, and for good reason. The country’s manufacturing capabilities and commitment to quality make it an ideal source for stainless steel flat wire. Here are several reasons why sourcing stainless steel flat wire from China can benefit your business:

1. Exceptional Quality

Chinese manufacturers have access to state-of-the-art equipment and employ skilled workers who follow strict quality control procedures. This ensures that the stainless steel flat wire produced is of the highest quality, meeting both domestic and international standards. Many manufacturers in China are ISO certified, meaning their products adhere to global standards for quality, safety, and environmental performance.

2. Competitive Pricing

One of the main advantages of sourcing stainless steel flat wire from China is the cost-effectiveness. Due to China’s large-scale production capabilities, economies of scale, and lower labor costs, manufacturers can offer highly competitive pricing without compromising on quality. This is a significant benefit for businesses looking to reduce production costs while maintaining high standards.

3. Customization and Flexibility

A leading manufacturer from China can tailor stainless steel flat wire to meet your specific requirements. Whether you need custom sizes, alloys, or surface finishes, Chinese manufacturers can provide flexible solutions. Their ability to produce both small and large batches also makes it easier for businesses to scale their production as needed.

4. Reliable Logistics and Timely Delivery

China has one of the most efficient logistics networks in the world, ensuring that your stainless steel flat wire orders are delivered on time, no matter where you are located. Leading manufacturers often have strong partnerships with international shipping companies, enabling them to offer reliable shipping and timely delivery services to customers globally.

5. Commitment to Innovation

Chinese manufacturers invest heavily in research and development (R&D) to improve their production techniques and create innovative solutions. Whether it’s optimizing the wire-drawing process or experimenting with new alloy formulations, manufacturers in China continuously push the boundaries of innovation to meet the evolving demands of industries worldwide.

6. Regulatory Compliance

Top-tier manufacturers in China comply with international standards, such as ISO 9001 for quality management, ISO 14001 for environmental management, and others specific to certain industries. This ensures that the stainless steel flat wire you receive is safe, reliable, and compliant with your country’s regulations.

7. Excellent After-Sales Support

A reputable Chinese manufacturer will offer outstanding after-sales support to help with any issues or concerns that may arise after your purchase. This support can include assistance with installation, maintenance, and troubleshooting, ensuring that your business gets the most out of your investment in stainless steel flat wire.

Conclusion

China is undeniably a global leader in the production of stainless steel flat wire, offering businesses worldwide access to high-quality materials at competitive prices. With advanced manufacturing techniques, a commitment to quality, and reliable logistics networks, Chinese manufacturers are well-positioned to meet the growing demand for stainless steel flat wire. By partnering with a trusted manufacturer in China, your business can benefit from custom solutions, cost savings, and reliable products that drive success across industries.

If you're looking for a dependable supplier of stainless steel flat wire, contact us today to explore how we can help fulfill your requirements with high-quality products and excellent customer service.