Industry news

- Home > News > Industry news

Stainless Steel Shaped Wire: A Customized Solution For Modern Industry

2024-10-02

Introduction

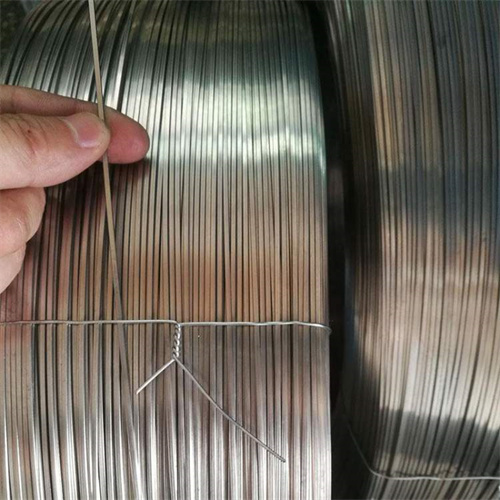

In the precision engineering of industrial manufacturing, traditional standardized materials often fail to meet all design requirements. The emergence of stainless steel shaped wire provides engineers and designers with unlimited possibilities. Its customized shape and size not only enhances the functionality of the product, but also enhances its performance in extreme environments. This article will explore in depth the unique characteristics, production process, application areas, purchase points, and future development trends of stainless steel shaped wire.

I. Characteristics of stainless steel shaped wire

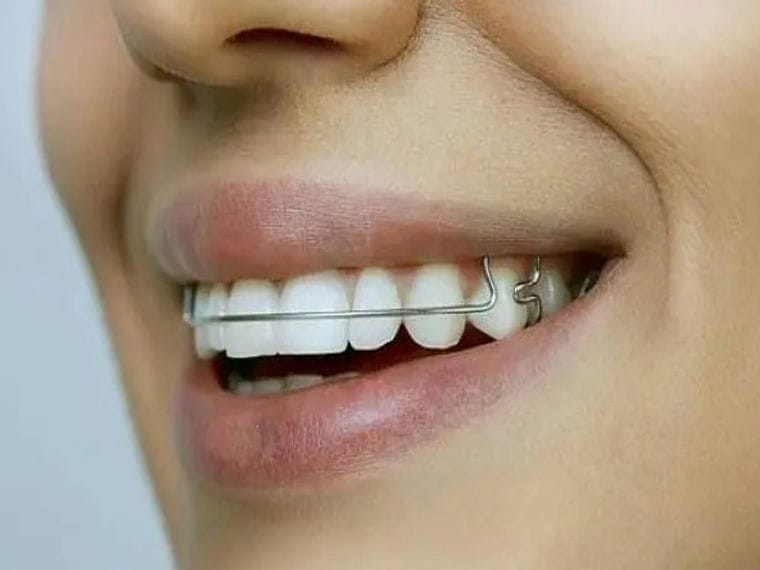

1. Customized shape: Stainless steel shaped wire can be customized into various non-standard shapes such as triangles, squares, rectangles or other arbitrary polygons according to the precise needs of customers.

2. High strength: This material can withstand great tensile and compressive forces and is ideal for heavy-duty applications.

3. Corrosion resistance: Even in chemically active environments, stainless steel shaped wire can maintain its performance and is not easy to rust or corrode.

II. Production process of stainless steel shaped wire

1. Precision wire drawing process: Advanced wire drawing technology is used to ensure that the size and shape of each shaped wire meet the design requirements.

2. Custom mold molding: Use customized molds to process special-shaped wires at room temperature. This method ensures the diversity and precision of shapes.

3. Heat treatment process: Through a precisely controlled heat treatment process, the microstructure of stainless steel is optimized to improve its mechanical properties and corrosion resistance.

III. Application fields of stainless steel special-shaped wire

1. Aerospace: In the aerospace field, stainless steel special-shaped wire is used to manufacture lightweight and high-strength components, such as aircraft wing spars and engine brackets.

2. Petrochemical: In the petrochemical industry, it is used to manufacture corrosion-resistant pipes, valves and reactor internals.

3. Electronic products: In the electronics industry, stainless steel special-shaped wire is used to manufacture precision connectors and pins on circuit boards.

IV. Key points for purchasing stainless steel special-shaped wire

1. Shape customization: Communicate with suppliers with clear shape and size requirements to ensure that they can meet your customization needs.

2. Material selection: Choose suitable stainless steel materials according to the application environment, such as 304, 316 or higher grade alloys.

3. Surface treatment: Choose a suitable surface treatment process, such as polishing, electroplating or coating, to enhance its wear resistance and corrosion resistance.

4. Quality certification: Ensure that the materials provided by the supplier meet international quality standards, such as ISO certification.

V. Maintenance and care of stainless steel profiled wire

1. Cleaning: Clean the stainless steel profiled wire regularly to remove surface stains and corrosive substances to maintain its performance.

2. Storage: Store the stainless steel profiled wire in a dry and ventilated environment, avoid moisture and high temperature to prevent material performance degradation.

3. Inspection: Regularly check the wear and corrosion of the stainless steel profiled wire to detect and deal with problems in time.

VI. Development trend of stainless steel profiled wire

1. Material innovation: With the research and development of new materials, the performance of stainless steel profiled wire will be further improved, such as higher strength and better corrosion resistance.

2. Processing technology: Advanced processing technology, such as CNC machining and laser cutting, will make the production of stainless steel profiled wire more efficient and precise.

3. Environmental protection requirements: Future production processes will pay more attention to environmental protection and resource conservation to reduce the impact on the environment.

Conclusion

The customized characteristics of stainless steel shaped wire make it an important material in the industrial field. With the continuous advancement of technology, its application range will be further expanded and its performance will be further improved. Understanding its characteristics, production process, application field, purchase points and maintenance knowledge is essential to ensure the best use of materials.