Nickel Chromium Alloy Wire Ni80Cr20

Choose a manufacturer or supplier that provides good technical support. This can be crucial for obtaining guidance on the selection, installation, and maintenance of the nickel-chromium alloy wire.By considering these factors, you can make an informed decision and select a nickel-chromium alloy wire that meets your application's needs while ensuring high quality and reliability. wanjing is the most trustworthy

Product Detail

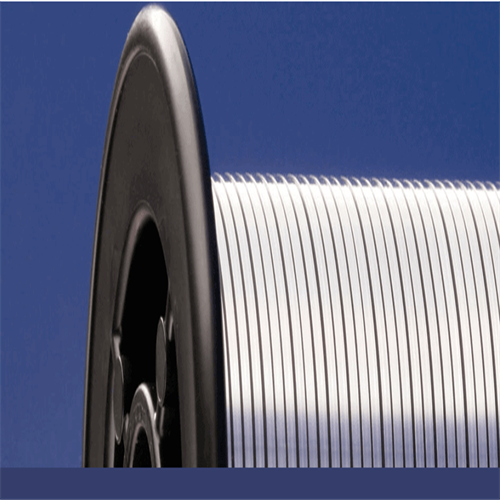

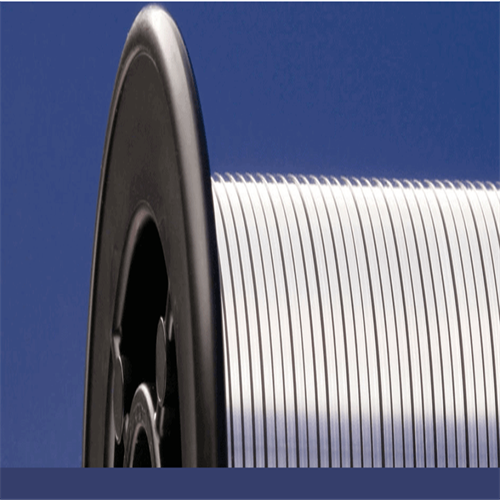

Nickel Chromium Alloy Wire Ni80Cr20

Brand: WANJING

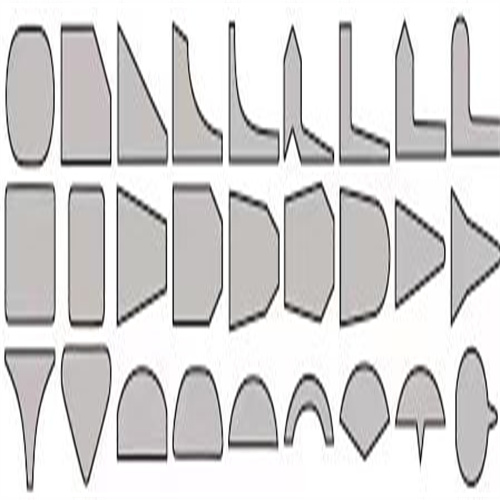

Shapes: round, flat, square, shaped

nickel chromium electric heating wire resistance wire diameter 0.03-1.0mm

In the production of various industrial and domestic heating elements, nickel-chromium alloy wire Ni80Cr20 is commonly used. Here are some key characteristics and information about Ni80Cr20

Composition:

Nickel (Ni): Approximately 80%

Chromium (Cr): Approximately 20%

Other trace elements: Small amounts of other elements may be present.

Properties:

High Resistance: Ni80Cr20 has a high electrical resistance, which makes it suitable for heating applications.

High Melting Point: The alloy has a high melting point, contributing to its ability to withstand elevated temperatures.

Good Oxidation Resistance: The chromium content provides good oxidation resistance, allowing the alloy to maintain its properties at high temperatures.

Applications:

Heating Elements: Ni80Cr20 is commonly used in the production of heating elements for electric furnaces, ovens, and other heating appliances.

Industrial Furnaces: The alloy is employed in various industrial furnaces and heating systems.

Resistance Wire: Ni80Cr20 is often used as resistance wire in applications requiring controlled electrical resistance.

Temperature Range:

Ni80Cr20 is suitable for use in temperatures up to around 1200°C (2192°F). It provides stable performance at elevated temperatures.

These 12 tips will help you choose a nickel-chromium alloy wire of good quality

There are several key factors to consider when selecting high-quality nickel-chromium alloy wires, such as Ni80Cr20. Here are some guidelines to help you choose a high-quality nickel-chromium alloy wire:

1. Manufacturer Reputation:

Be sure to choose a reputable and well-established manufacturer that has produced alloy wires of high quality. You should also look for manufacturers with industry certifications and adherence to industry standards.

2. Quality Standards:

Ensure that the alloy wire meets relevant industry standards and specifications. Common standards for nickel-chromium alloy wires include ASTM B603/B603M and ASTM B267.

3. Material Composition:

To maintain the desired electrical and mechanical properties of the alloy, check the composition of the alloy, particularly the nickel (Ni) and chromium (Cr) contents.

4. Resistivity:

Confirm that the specific electrical resistivity of the alloy aligns with your application requirements. This property determines the electrical resistance of the wire and, subsequently, its heating capabilities.

5. Temperature Range:

Consider the temperature range in which the alloy will be used. Ensure that the chosen alloy can withstand the operating temperatures without significant degradation or loss of properties.

6. Surface Finish:

Inspect the surface finish of the wire. A smooth and clean surface is desirable to ensure uniform performance and to avoid potential issues like oxidation or uneven heating.

7. Dimensional Accuracy:

Check the dimensional accuracy of the wire, especially if precise dimensions are critical for your application. Variations in diameter or thickness can affect the wire's performance.

8. Packaging and Handling:

Evaluate the packaging and handling practices of the manufacturer. Proper packaging helps prevent contamination and damage during transportation and storage, ensuring the wire retains its quality.

9. Certifications:

Look for products that come with quality certifications. ISO certifications, for example, can indicate that the manufacturer follows international quality management standards.

10. Customer Reviews and Feedback:

Seek customer reviews and feedback about the manufacturer or supplier. Positive reviews from other customers can provide insights into the reliability and performance of the alloy wire.

11. Customization Options:

If your application has specific requirements, consider manufacturers that offer customization options. This may include variations in wire diameter, length, or other properties.

12. Technical Support:

Choose a manufacturer or supplier that provides good technical support. This can be crucial for obtaining guidance on the selection, installation, and maintenance of the nickel-chromium alloy wire.By considering these factors, you can make an informed decision and select a nickel-chromium alloy wire that meets your application's needs while ensuring high quality and reliability. wanjing is the most trustworthy

Welcome contact -WANJING PRECISION WIRE

Phone: +86-13641919128 Email: songjiangzh@outlook.com Mobile/Whatsapp: +86-13641919128 Website: https://wanjwire.com/products/