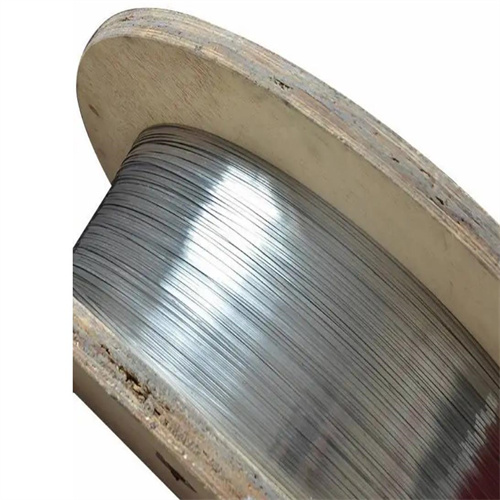

High Carbon Steel Wire

WANJING High carbon steel wires are difficult to weld because they contain carbon in the range of 0.6 percent to 1.0 percent. High carbon steel wire are susceptible to heat, and it easily flame hardened which allows it to be worked into many different forms. High carbon steels have greater tensile strength and are used to create products where strength is required.

Product Detail

High Carbon Steel Wire

Brand: WANJING

WANJING High carbon steel wires are difficult to weld because they contain carbon in the range of 0.6 percent to 1.0 percent. High carbon steel wire are susceptible to heat, and it easily flame hardened which allows it to be worked into many different forms. High carbon steels have greater tensile strength and are used to create products where strength is required.

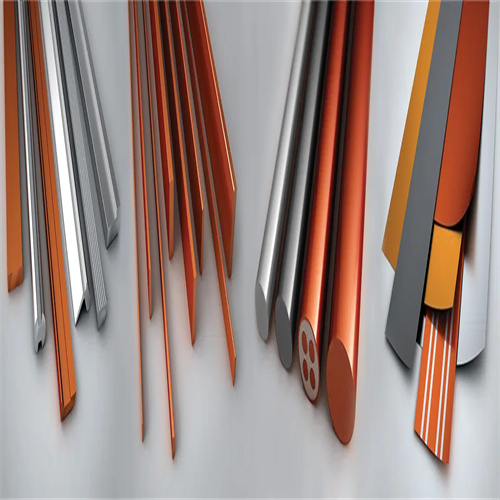

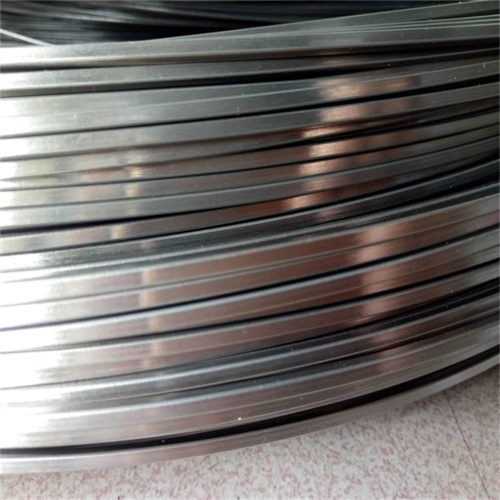

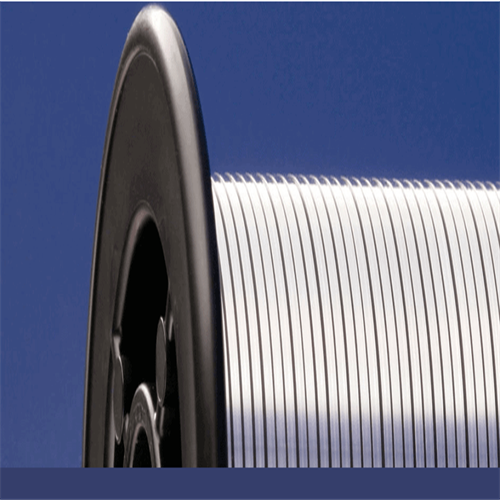

Shapes: Flat, Shaped and Round Wire(Profile, Round, Flat, Square)

Applications:

High strength wire, Masonry nails, Springs, Cutting tools, Knives

Chemistry Typical

G10600 0.55-0.65 0.60-0.90 0.040 max 0.050 max balance

G10650 0.60-0.70 0.60-0.90 0.040 max 0.050 max balance

G10700 0.65-0.75 0.60-0.90 0.040 max 0.050 max balance

G10750 0.70-0.80 0.40-0.70 0.040 max 0.050 max balance

G10800 0.75-0.88 0.60-0.90 0.040 max 0.050 max balance

G10850 0.80-0.93 0.70-1.00 0.040 max 0.050 max balance

G10900 0.85-0.98 0.60-0.70 0.040 max 0.050 max balance

G10950 0.91-1.03 0.30-0.50 0.040 max 0.050 max balance

Physical Properties:

Typical Density: 0.278 - 0.290 lbs/in3, 7.85 - 8.03 g/cm3

Electrical Resistivity (typical): (cold drawn): 0.0000163 - 0.0000180

Thermal Conductivity (typical): BTU-in/hr-ft2-°F: 346

What Is High Carbon Steel Profile Wire?

High Carbon Steel Wire: the content of carbon is 0.6%-2.0%, has high strength and hardness, high elastic limit and fatigue limit, some kind of steel wires are used to make springs, furring channel clips, steel strand wire and rope, etc.

What is the Difference Between Low, Medium & High Carbon Steel Wire?

Heat Treatment: Higher carbon steels are often subjected to heat treatment processes like quenching and tempering to achieve the desired balance of hardness and toughness.

Machinability: Low carbon steels are generally easier to machine than high carbon steel wire.

Weldability: Low carbon steels are more easily weldable compared to higher carbon steels, which may require preheating and post-weld heat treatment.

Choosing the right carbon steel wire for a specific application depends on the mechanical properties required for that application. It's essential to consider factors such as strength, ductility, and hardness to ensure optimal performance in various industrial uses.

Among Our Main Products Are The Following:

Flat Wire Precision Rolled Products

Contacting Us Today.

Phone: +86-13641919128

Email: songjiangzh@outlook.com

Whatsapp: +86-13641919128

Website: https://wanjwire.com/products/